Raised in Gouveia, a beautiful area of Portugal, these hens are housed in a brand new facility designed for their well-being and the efficiency of their production.

Quinta do Caramuja is an established organic egg producer in Portugal. It has several organic production facilities, and has turned to us to further expand its production capacity to meet the growing demand.

The customer chose us for our ability to provide a turnkey project, which included the construction of the shed, the supply of the aviary system, environmental control, automation for egg packaging, electrical installation, and lighting.

How did we act?

The customer was advised to use a Tecno AS-C250 aviary with central egg collection due to the robustness of the system, its ease of use, and its characteristics which are well suited to the production of organic eggs.

A 83 m long, 13 m wide and 3 m high structure was designed with two Tecno AS-C250 aviaries inside with central egg collection for a total capacity of 9,000 hens.

As in all Tecno solutions, the care can be seen from the attention we pay to each single element: the layers can access the double nest from each side of the aviary, and at the entrance of each nest there is a line of drinkers that attracts them towards the nesting area.

On the first floor of the system there is a feeder circuit and an additional line of drinking nipples. Above the nests there is another floor with another feeder circuit, in this case without drinking troughs, to encourage the hens to move around the system and not to constantly remain in this level.

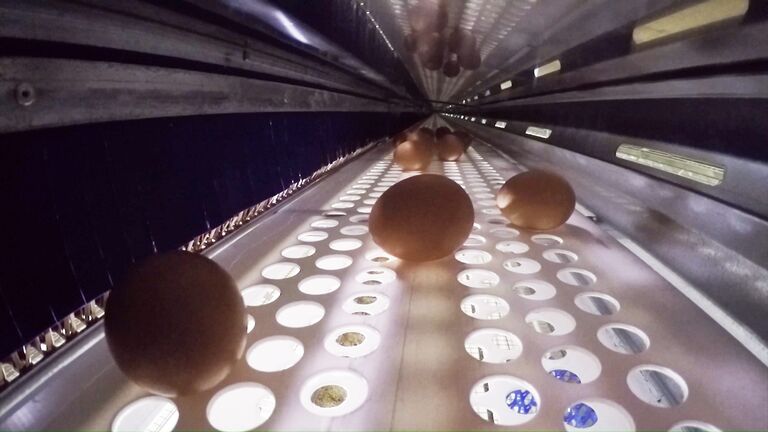

The central egg collection uses a 50cm wide belt and the nest has a self-closing ejection system that helps keep the area clean and prevents the hens from staying in the nest overnight.

The lighting of the corridors and inside the system takes place by means of dimmable LED tubes that allows the farmer to adjust the level of brightness to the needs of the hens, both during the different phases of their life and during each daily cycle.

The environmental control system controls the automatic opening of the windows and activates the internal fans to optimize the recirculation of the air, it also has a cooling system using a high pressure misting system.

What are the advantages for the customer?

The entire aviary is controlled by an intuitive customized touch screen PLC for simple management of the system, display of the data can be collected also via the internet and also from a smartphone.

The entire project, from the feasibility study and installation, up to the start-up of all the equipment, was managed in collaboration with Ingeniería Avícola of Valladolid, our historic dealer operating in the Iberian Peninsula, allowing the customer to interface with a single supplier and simplifying the construction of the new operation.